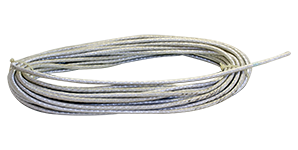

The

term litz wire is derived from the German word litzendraht meaning

woven wire. Generally defined, it is a wire constructed of individually

film insulated wires bunched or braided together in a uniform

pattern of twists and length of lays. The multistrand configuration

minimizes the power losses otherwise encountered in a solid conductor

due

to the skin effect or tendency of radio frequency current to

be concentrated at the surface of the conductor. In order to

counteract this effect, it is necessary to increase the amount

of surface area without appreciably increasing the size of

the conductor. It is also essential to position each individual

strand

in the litz construction in a uniform pattern moving from the

center to the outside and back in a given length. Efficiency

of the stranded conductor can be multiplied by increasing the

number of twists per foot. Generally, six to eight twists per

foot is common. All three of our selections have 40 twists

per foot, creating a much more electrically efficient and costly

to produce.

Our Litz wire was made by Kerrigan

Lewis. The current industry standard insulation is a polyurethane

film for insulating individual strands because of its low

electrical losses

and its solderability. Additionally, our wire has "Heavy Nyleze",

an extra thick coating. THIS FILM BURNS AWAY IN THE SOLDERING PROCESS!

Some litz wires are further insulated with a single or double wrap,

or serving of a textile, typically nylon. Our 12/36 is so covered.

The 7/36 and 8/36 are unserved. |